FACE MIXED PAVERS

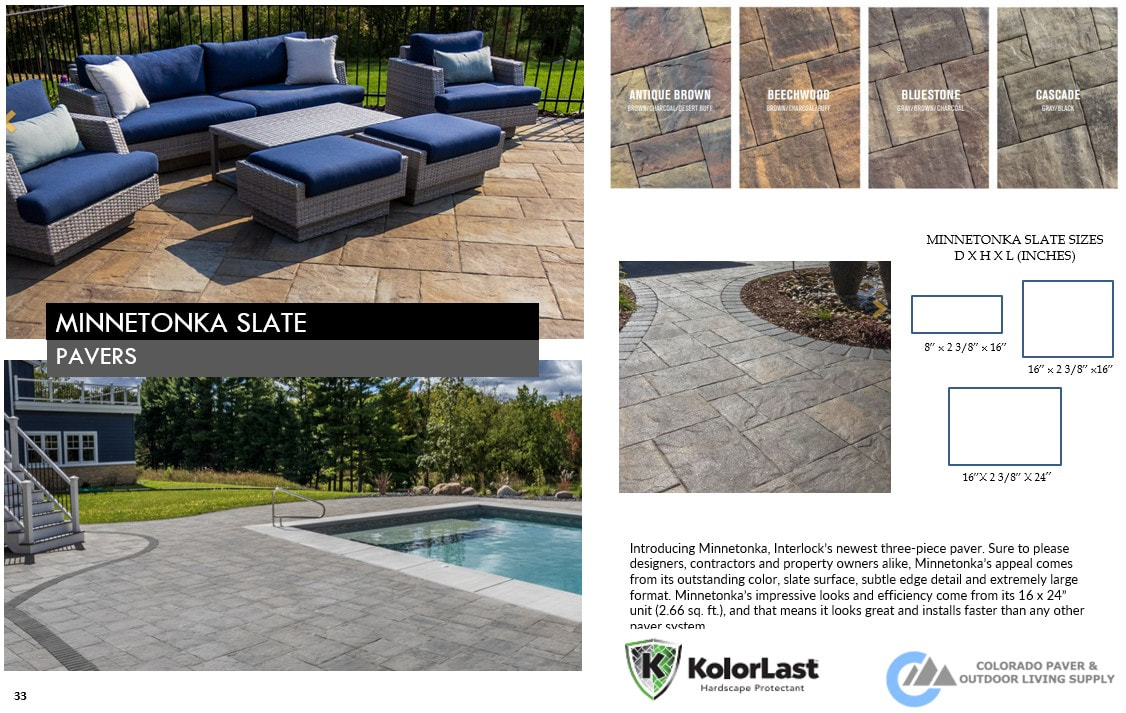

Unveil the Elegance: Face-Mixed Concrete PaversThe Magic of Face Mixing:Unlike traditional concrete pavers, face-mixed pavers bring a vivid top layer to life. By mixing a concentrated color layer on the face of the paver, these beauties offer an unmatched vibrancy and surface appeal, setting the gold standard in hardscape elegance.

Why Choose Face-Mixed Concrete Pavers?

For Designers: Push the boundaries of your design visions. With the distinct character of face-mixed pavers, create spaces that resonate with charm and sophistication, ensuring your projects stand out in the best way.

Bring Your Spaces to Life!

Dive into the world of face-mixed concrete pavers and elevate your designs to new horizons. Let the colors and textures pave the way for memories, laughter, and timeless moments.

Why Choose Face-Mixed Concrete Pavers?

- Rich & Lasting Color: The face-mixed technique allows for a richer concentration of pigments on the paver's surface, offering a vibrant and long-lasting hue that doesn’t fade easily over time.

- Distinct Aesthetics: With a smooth, detailed finish on top, face-mixed pavers stand out, offering homeowners and designers a unique visual appeal.

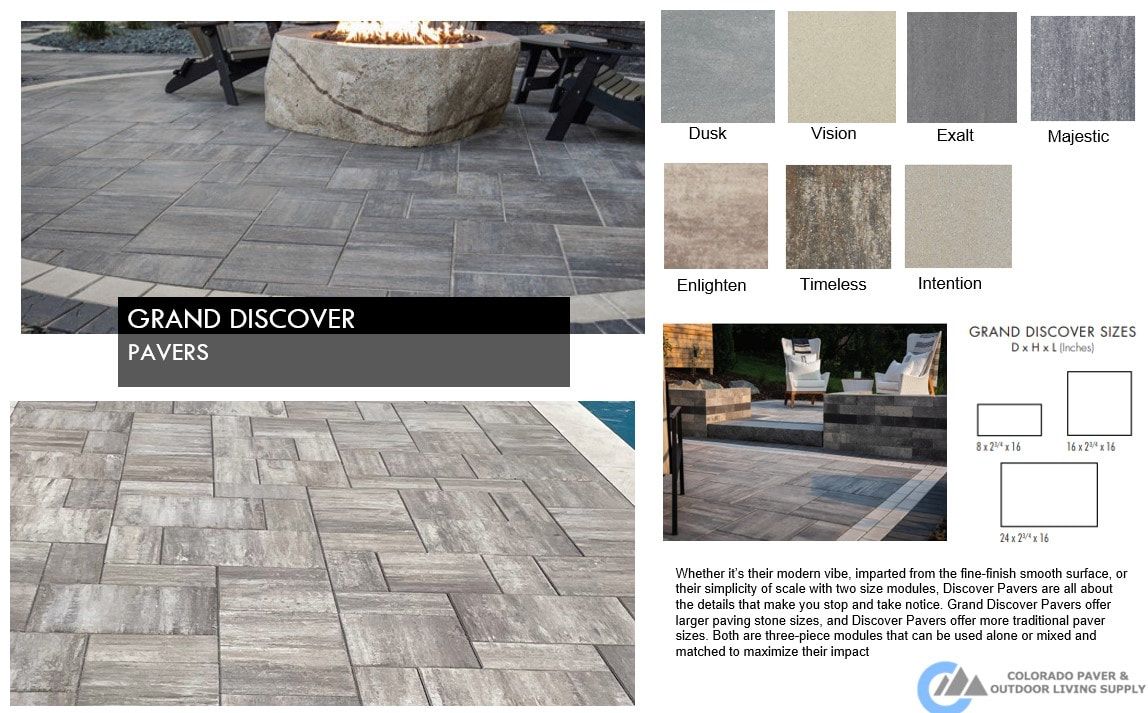

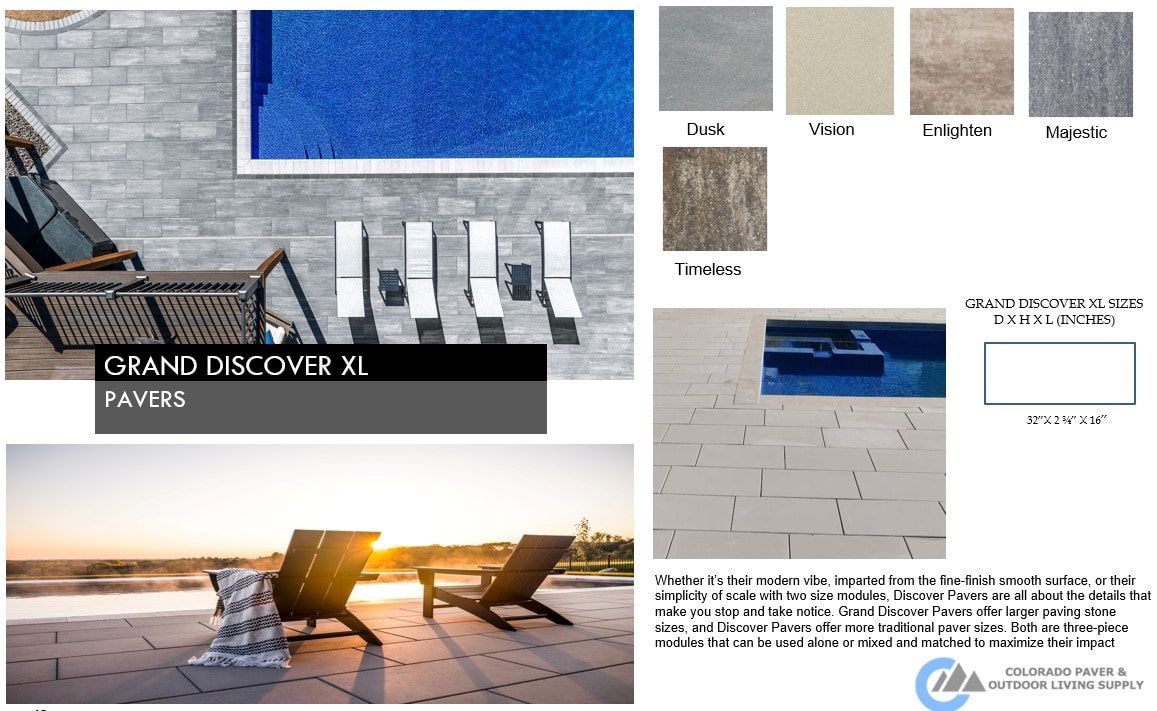

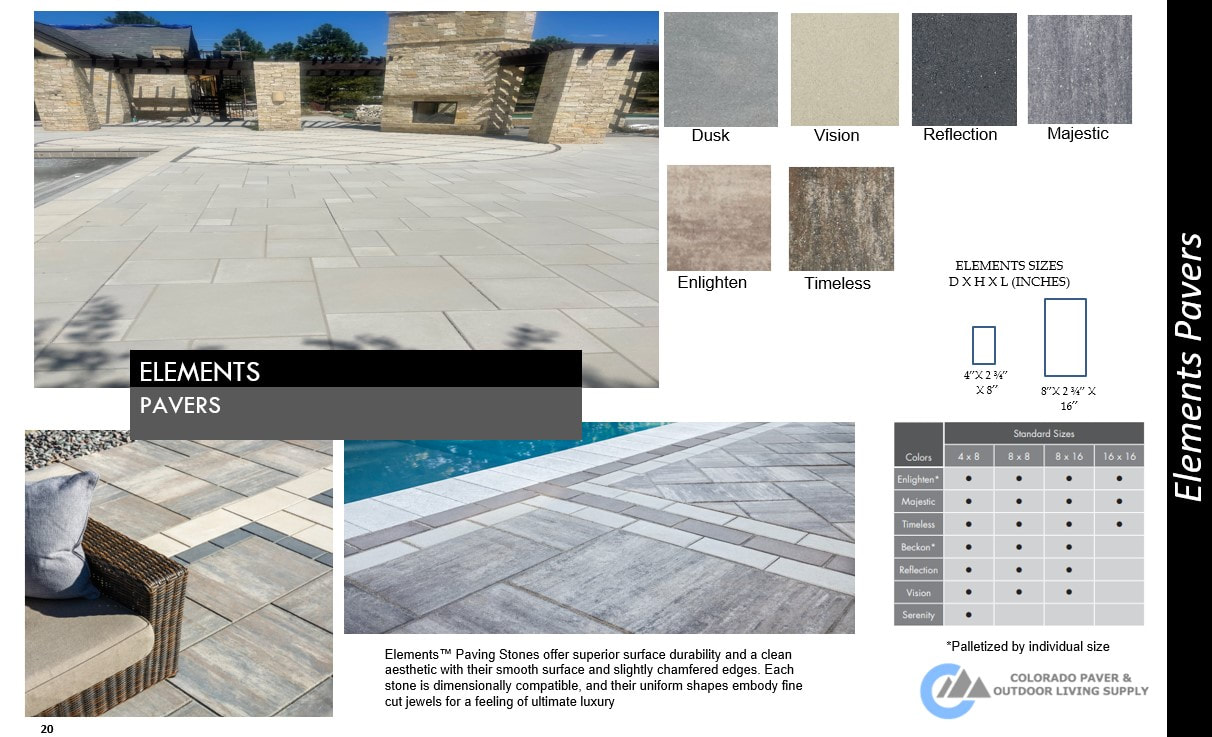

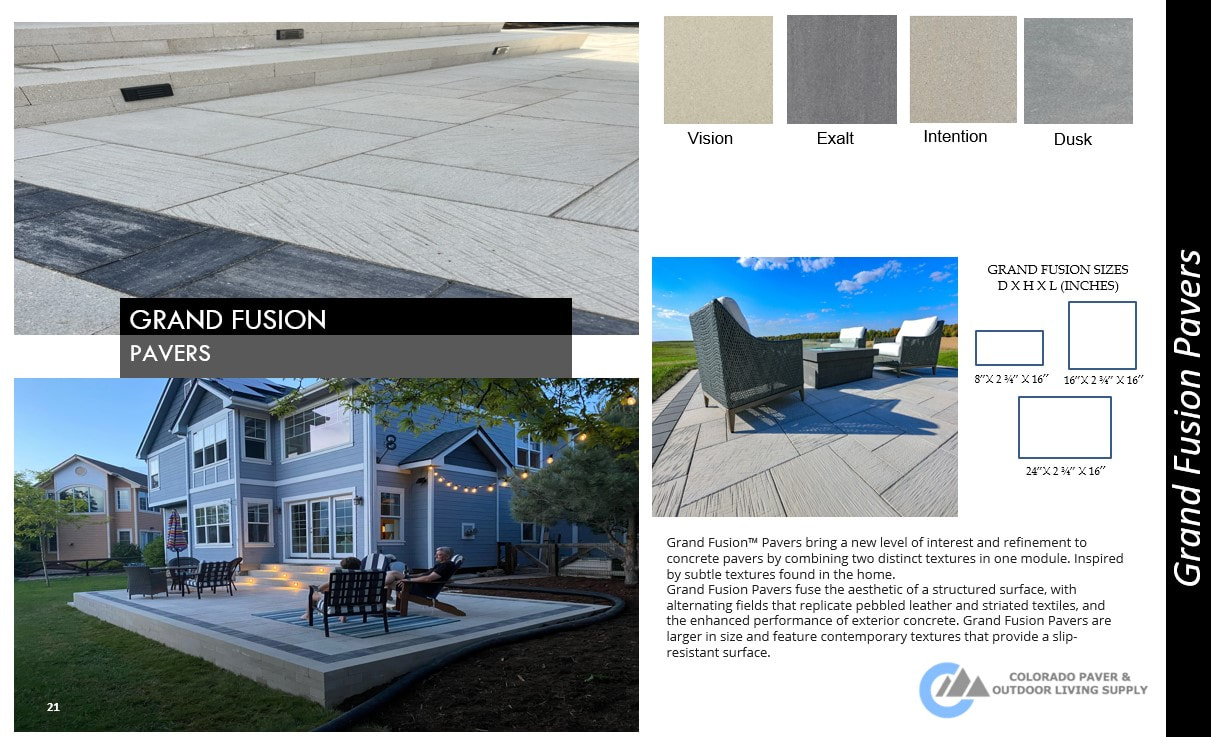

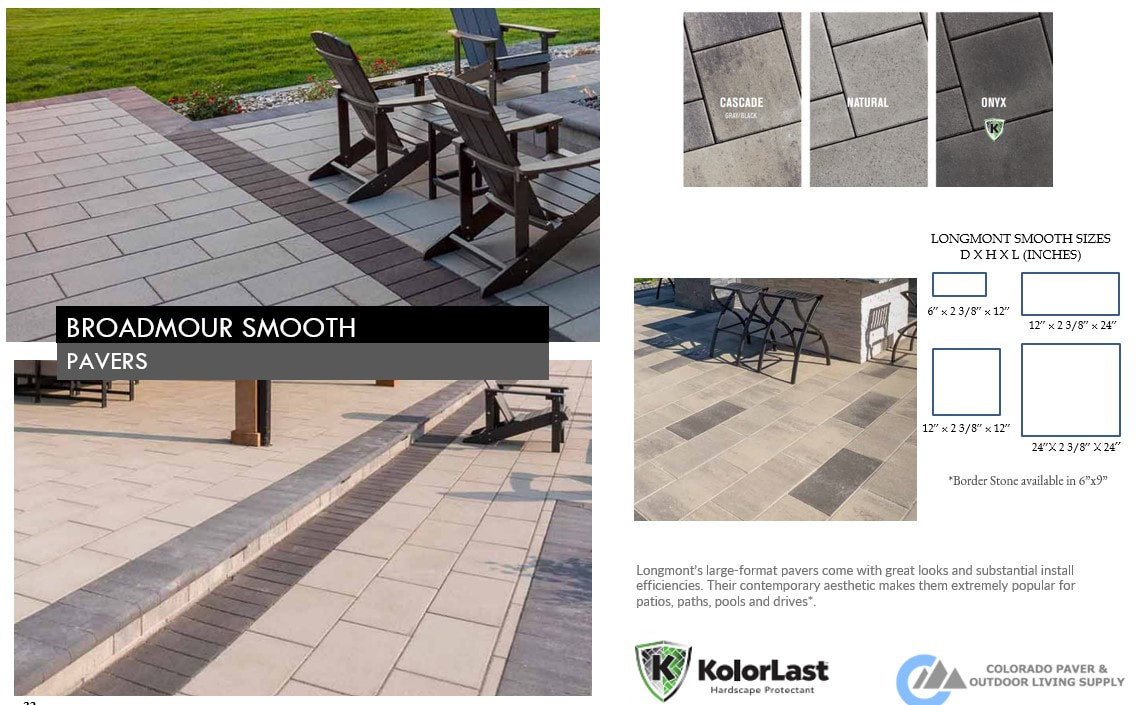

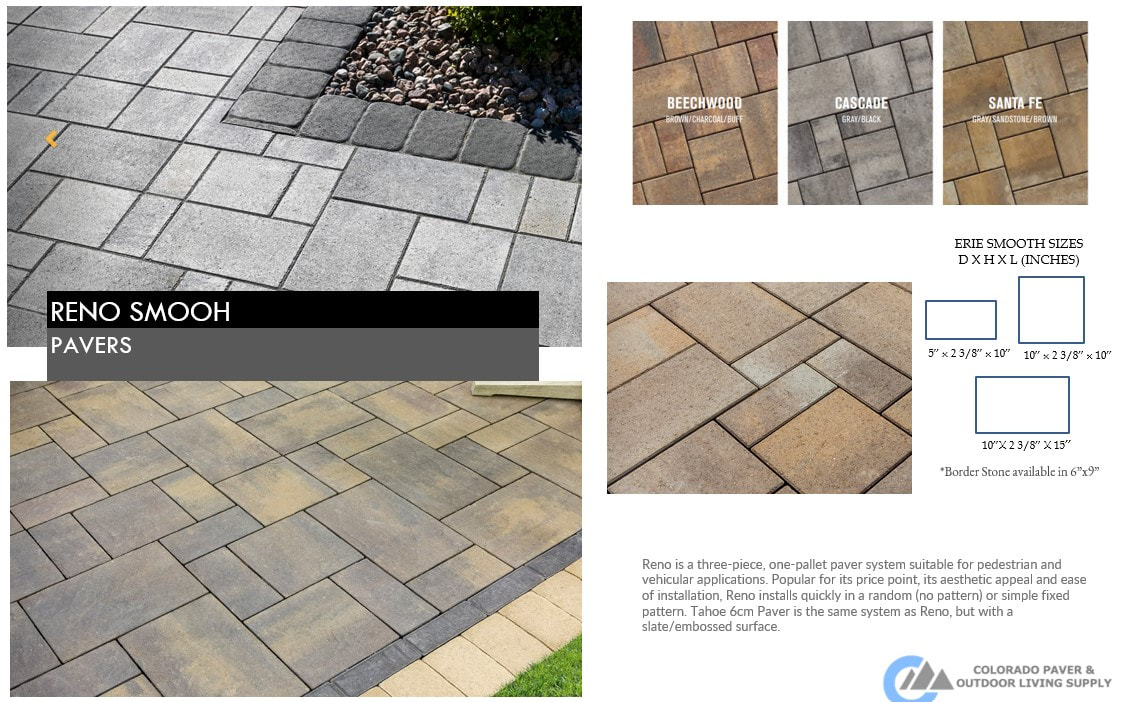

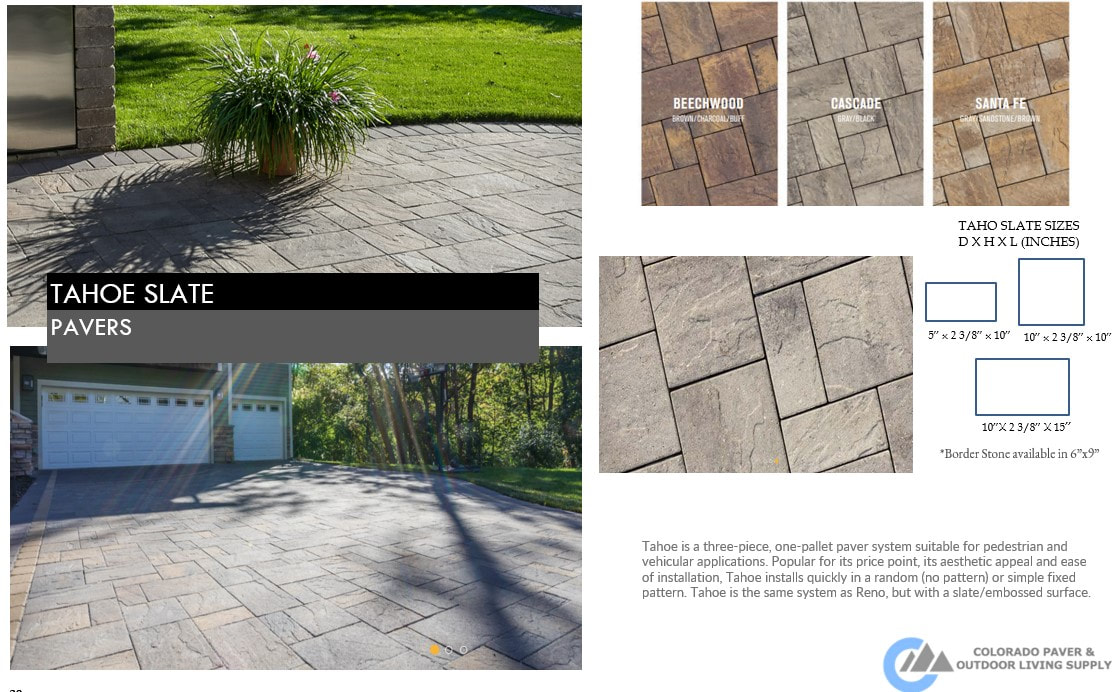

- Versatile Design: Available in a plethora of shapes, sizes, and colors, face-mixed pavers can be tailored to fit any design vision, from the contemporary urban garden to the serene countryside patio.

- Durability with Charm: While the surface showcases the beauty, the underlying structure remains as robust as any high-quality concrete paver, promising durability and longevity.

For Designers: Push the boundaries of your design visions. With the distinct character of face-mixed pavers, create spaces that resonate with charm and sophistication, ensuring your projects stand out in the best way.

Bring Your Spaces to Life!

Dive into the world of face-mixed concrete pavers and elevate your designs to new horizons. Let the colors and textures pave the way for memories, laughter, and timeless moments.

Through Mixed Pavers & Kolorlast Inline Sealer

Paving the Future: Through-Mixed & In-line Sealed Concrete PaversThrough-Mixed Concrete Pavers:These pavers aren’t just surface deep. Their consistency runs throughout, promising a visual appeal that's not just on the outside but built into the very core.

Benefits:

Benefits:

Advantages of Kolorlast Pavers:

For Designers: Elevate your designs by choosing pavers that guarantee lasting beauty. With Kolorlast, create outdoor spaces that remain as vibrant as your vision, pleasing clients for years to come.

Designing with a Difference:For Homeowners: Choose pavers that don’t just look good but offer you the longevity and ease of maintenance you desire. Let your patios, driveways, and walkways be a testament to quality and beauty that stands the test of time.

For Designers: Give your projects a cutting edge. With through-mixed and in-line sealed pavers, ensure that your designs remain impeccable for years, pleasing your clients and enhancing your portfolio.

Lay the Foundation of Excellence!

Explore our range of through-mixed and in-line sealed concrete pavers. Where innovation meets aesthetics, let’s build spaces that inspire.

Benefits:

- Consistent Color: Through-mixing ensures that even if the paver's surface is chipped or worn, the color beneath remains the same, preserving the aesthetics.

- Durability: Uniformly mixed materials mean fewer weak points and a longer-lasting paver.

- Value for Money: With color and strength permeating every inch, you get maximum value for every square foot.

Benefits:

- Stain Resistance: In-line sealed pavers resist stains, ensuring accidental spills don’t become permanent eyesores.

- UV Protection: The sealing process helps in deflecting harmful UV rays, ensuring that the vibrant colors don’t fade easily under the sun.

- Maintenance Ease: Sealed surfaces are easier to clean and require less frequent resealing, offering homeowners a hassle-free experience.

- Enhanced Beauty: The sealing gives the paver a gentle sheen, enhancing the overall aesthetic appeal of the paved area.

Advantages of Kolorlast Pavers:

- Superior UV Resistance: Kolorlast provides unmatched protection against the sun's harsh rays, ensuring that the vibrant colors of your pavers remain unchanged for years.

- Environmental Defense: Whether it's the acidity from rainfall or pollutants in the air, Kolorlast offers a shield, maintaining the paver's original aesthetic appeal.

- Extended Lifespan: With Kolorlast, not only do your pavers look good, but they also last longer, offering excellent value for your investment.

- Easy Maintenance: A surface treated with Kolorlast is easier to clean and requires minimal upkeep, letting you enjoy your outdoor spaces without the constant need for maintenance.

For Designers: Elevate your designs by choosing pavers that guarantee lasting beauty. With Kolorlast, create outdoor spaces that remain as vibrant as your vision, pleasing clients for years to come.

Designing with a Difference:For Homeowners: Choose pavers that don’t just look good but offer you the longevity and ease of maintenance you desire. Let your patios, driveways, and walkways be a testament to quality and beauty that stands the test of time.

For Designers: Give your projects a cutting edge. With through-mixed and in-line sealed pavers, ensure that your designs remain impeccable for years, pleasing your clients and enhancing your portfolio.

Lay the Foundation of Excellence!

Explore our range of through-mixed and in-line sealed concrete pavers. Where innovation meets aesthetics, let’s build spaces that inspire.